Washable RFID Fabric Tags Reshape Industrial Laundering

Washable RFID fabric tags differ from traditional rigid RFID tags by integrating ultra-thin, flexible chips (as thin as 0.1mm) with durable textile substrates—typically polyester-cotton blends or high-performance fabrics like aramid—treated with water-resistant, heat-resistant, and chemical-resistant coatings. Recent technical advancements have pushed their durability to new heights: leading products now withstand 500+ industrial wash cycles at 95°C (203°F), chemical bleaching, high-pressure tumble drying, and even steam sterilization—critical for healthcare and hospitality applications.

Key market drivers include:

Stringent Compliance Requirements: Healthcare regulators in the EU (via EN ISO 13485) and the U.S. (FDA) mandate traceability of medical textiles (e.g., surgical gowns, bed linens) to prevent cross-contamination, driving hospitals to adopt RFID-enabled tracking.

Operational Efficiency Gains: Industrial launderers report 30-40% reductions in textile loss and 25% faster processing times after deploying washable RFID tags, as automated readers eliminate manual counting errors.

Rising Demand in Hospitality: Global hotel chains are scaling adoption to track linens, towels, and uniforms across properties—Marriott alone aims to equip 100 million textile items with washable RFID tags by 2026.

Regionally, Europe leads the market with a 38% share in 2025, fueled by strict healthcare regulations and mature hospitality sectors. Asia-Pacific is the fastest-growing region (CAGR 22.3%), driven by expanding manufacturing hubs in China, India, and Southeast Asia, where garment factories use washable tags for workwear tracking.

Global Flagship Projects & Industry Applications

1. Healthcare: Sterile Textile Traceability

The UK’s National Health Service (NHS) launched a nationwide washable RFID tag initiative in 2024, equipping 50 million medical textiles across 1,200 hospitals. The tags, supplied by UK-based company Checkpoint Systems, integrate HF (13.56MHz) RFID chips compliant with ISO 15693 standards, enabling real-time tracking of surgical drapes, scrub suits, and bed linens through laundering, sterilization, and hospital distribution. Early results show a 60% reduction in textile loss and a 45% decrease in time spent on inventory management, freeing up staff for patient care.

In Germany, DKV Health (Europe’s largest health insurer) partnered with RFID firm Smartrac to deploy UHF (868MHz) washable fabric tags for home healthcare textiles. The tags withstand 800 wash cycles and transmit data to cloud-based platforms, allowing DKV to verify cleaning compliance and optimize textile rotation.

2. Hospitality: Cross-Property Textile Management

Marriott International’s “Smart Linen” program, launched in 2025, uses washable RFID fabric tags from Avery Dennison for linens and uniforms across 3,000+ hotels in Europe and Asia. The tags are sewn into linens (hidden from guests) and paired with readers at laundries, hotel storage rooms, and housekeeping carts. This system has reduced linen replacement costs by 35% at pilot properties in Paris and Singapore, as managers can pinpoint missing items in real time and prevent over-ordering.

Dubai’s Jumeirah Group went a step further, integrating washable RFID tags with IoT sensors to monitor textile quality—tracking factors like fabric wear, stain accumulation, and washing cycle count. The data helps the group optimize linen replacement schedules, cutting waste by 28%.

3. Manufacturing & Workwear Tracking

Volkswagen Group deployed washable RFID fabric tags for 1.2 million employee workwear items (e.g., overalls, gloves, safety jackets) across 15 manufacturing plants in Europe and Mexico. The UHF tags, supplied by NXP Semiconductors, withstand industrial washing, chemical exposure, and high-temperature drying. The system automates workwear distribution, tracks usage cycles, and ensures compliance with safety gear replacement schedules—reducing administrative costs by 40% and improving workplace safety.

In India, garment manufacturer Arvind Limited uses washable RFID tags to track raw material textiles (e.g., cotton rolls, denim) through production and laundering processes. The tags provide real-time visibility into inventory movement, cutting lead times by 22% and minimizing production delays.

Core Advantages: Why Washable RFID Fabric Tags Outperform Alternatives

Unmatched Durability for Harsh Environments

Unlike rigid plastic RFID tags (which crack or detach after 50-100 washes) or paper labels (which disintegrate instantly), washable fabric tags are designed for industrial laundering. Leading products like Avery Dennison’s AD-2290 can withstand pH levels of 2-12 (resisting bleach and detergents), temperatures up to 134°C (steam sterilization), and mechanical stress from high-speed washers and dryers.

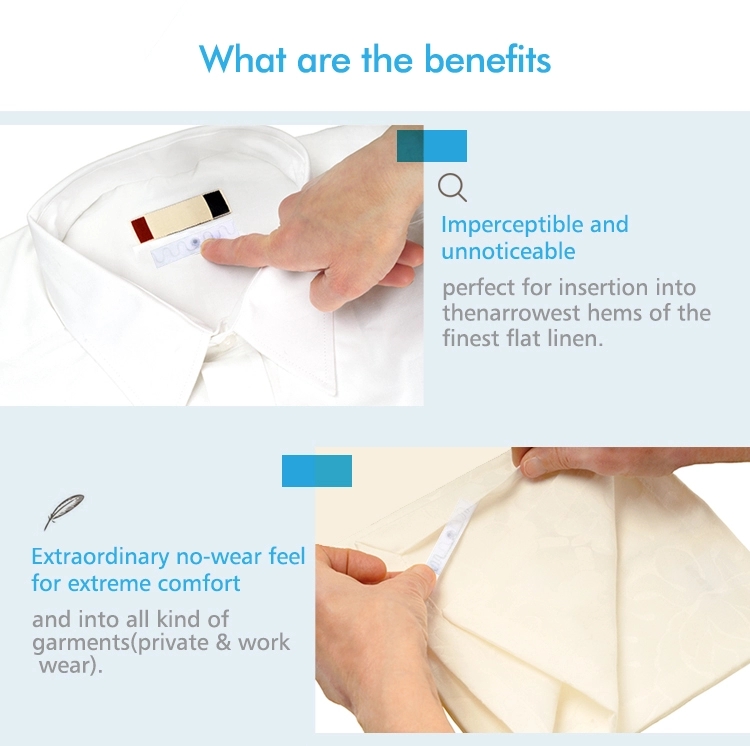

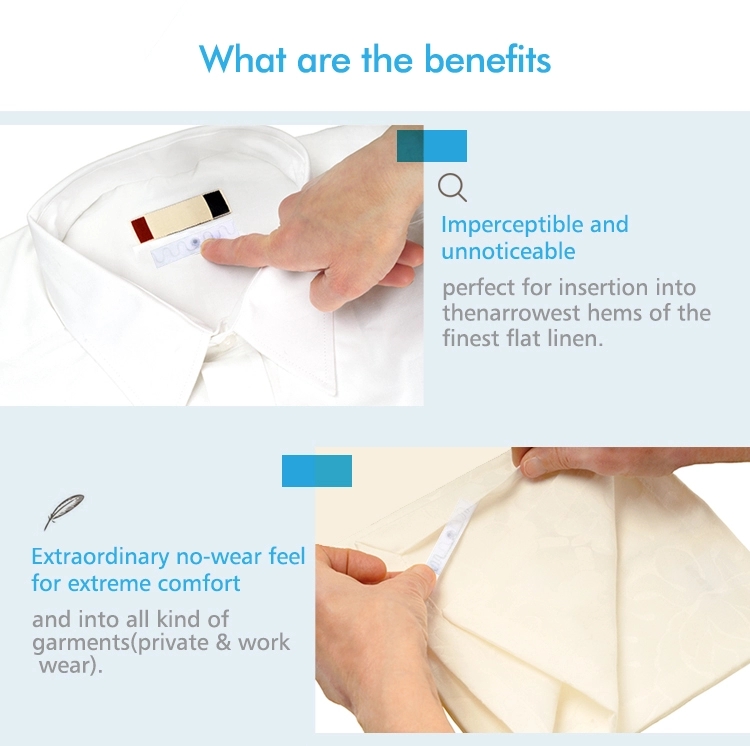

Seamless Integration & Discretion

Washable fabric tags are thin, flexible, and can be sewn into textiles without affecting comfort or appearance—critical for healthcare garments and hospitality linens. They can also be customized to match fabric colors, making them nearly invisible to end-users.

Enhanced Traceability & Data Insights

RFID technology enables automated, non-line-of-sight reading—meaning multiple tagged textiles can be scanned simultaneously as they move through laundries or storage facilities. Cloud-based platforms integrate tag data to provide analytics on textile usage, wash cycles, and inventory levels, helping businesses optimize operations and reduce costs.

Compliance & Safety

For regulated industries like healthcare, washable RFID tags provide an immutable audit trail of textile cleaning and sterilization, helping organizations meet regulatory requirements and prevent cross-contamination. In manufacturing, they ensure safety gear is replaced on schedule, reducing workplace hazards.

Future Trajectory: Innovation & Market Expansion

The next wave of innovation will focus on integrating washable RFID fabric tags with advanced technologies:

Sensor-Embedded Tags: Pilot projects in Japan are testing tags with built-in temperature and humidity sensors to monitor textile storage conditions, preventing mold growth in hospitality linens.

Low-Power Wide-Area (LPWA) Connectivity: Companies like Semtech are developing UHF RFID tags with LoRaWAN integration, enabling long-range tracking of textiles across large facilities (e.g., warehouse campuses).

Sustainable Materials: As sustainability becomes a priority, manufacturers are developing washable tags using recycled textiles and biodegradable coatings—Coca-Cola’s European bottling plants recently adopted such tags for employee uniforms.

Leading market players are expanding their footprints: Smartrac opened a new production facility in Vietnam in 2025 to meet Asian demand, while Checkpoint Systems acquired textile RFID firm TexTrace to strengthen its healthcare portfolio.

“The washable RFID fabric tag market is at an inflection point,” says Sarah Chen, Senior Analyst at IDTechEx. “As industries prioritize traceability, efficiency, and compliance, these tags are no longer a ‘nice-to-have’ but a ‘must-have’—and we expect adoption to accelerate in emerging sectors like sports apparel and senior care in the coming years.”